The possibility of returning a product is a philosophy to which the customers have been getting used to. However, for some companies, this gesture of goodwill can be very costly.

Usually, companies have focused on the delivery of products to customers, ignoring return as a part of the supply chain, when really, an effective reverse supply chain can give way to more satisfied customers and generate higher profits.

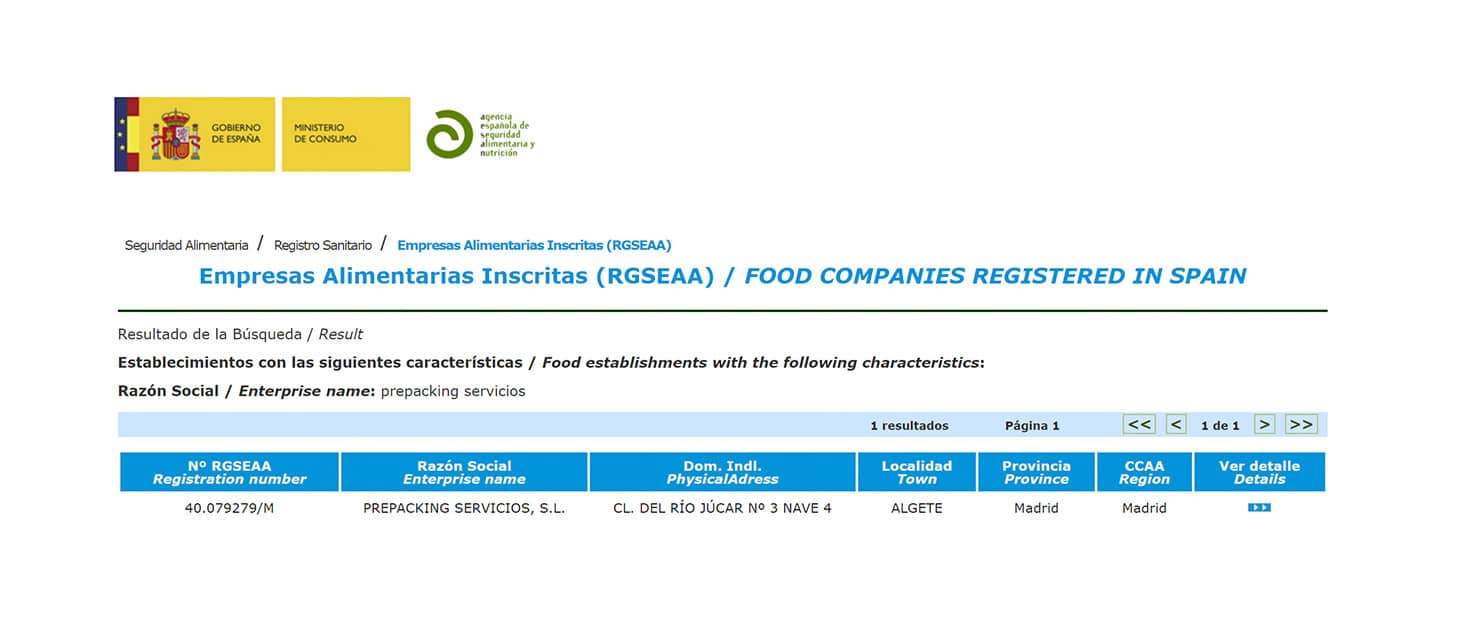

Prepacking extends its services offer with regard to reverse logistics.

Prepacking implemented, to satisfy the need of several of its customers, what is now called reverse logistics. This allowed and allows our clients to have specific solutions to plan and control the flow of materials and to have all the necessary information about the return of goods to its supply chain or its stock, providing a valuable information to face the fundamental causes which help to reduce the number of returns and minimise the costs associated to the return of the goods, looking for the maximum effectiveness.

These solutions include: co-ordination of collection in the final client, changes, reverse transport, classification and checking of the product, management of differentiated goods, relabelling, packaging, reconditioning and availability, All the above to provide value to materials that in another way would not be complete, and would not be suitable for sale or for their use (Merchandising Material, Demo-displays), even assuming the task of waste disposal on a green dot, or the destruction of the material with the necessary guarantees.

If the client wishes so, all this work is offered with a wide report, even photographic and automatic, about the difference between what is sent and what is received, in a way that the client’s management is made easier, so that the client is exclusively dedicated to its business.

As exquisite control requirements are needed, these systems are always designed and developed in a close relationship with people in charge of a maximum level within the client.